Carbon Footprint of the Serres 2l Suction Bag

In our pursuit of understanding and reducing our environmental impact, we began on a journey to evaluate the carbon footprint of our 2l suction bag’s entire life cycle. We utilized a comprehensive cradle-to-grave* methodology in our study case. Our production site is in Kauhajoki Finland and the end of life cycle / disposal was in Rotterdam Hospital in the Netherlands. We used this example in our study case as most of our shipments are done to central Europe. Our calculations showed us significant reductions in the CO₂e emissions from the waste disposal phase.

More details about our approach to sustainability can be found in our new Sustainability Report 2023. Read more details and download the full sustainability report here:

Our scenario

Patient liquids are considered hazardous waste and are typically disposed of by incineration. We already knew that incineration causes a noticeable impact on the environment and therefore chose the following scenario:

- Full 2l Serres Suction bag

- Emptied 2l Serres Suction bag, (emptied with Serres Nemo suction bag emptying device)

Calculation approach and inventory analysis

A comprehensive cradle-to-grave* methodology was employed to evaluate the suction bag’s life cycle and the calculation was performed with reference to the GHG protocol and the ISO 14044:2006 standards, but only taking CO₂e (Carbon Dioxide Equivalent) emissions into account.

The energy and material inputs and environmental outputs were assessed with an inventory analysis **. To assess the potential climate change impact associated with CO₂e emissions, we conducted an impact assessment. Other emissions and other environmental impact categories were excluded.

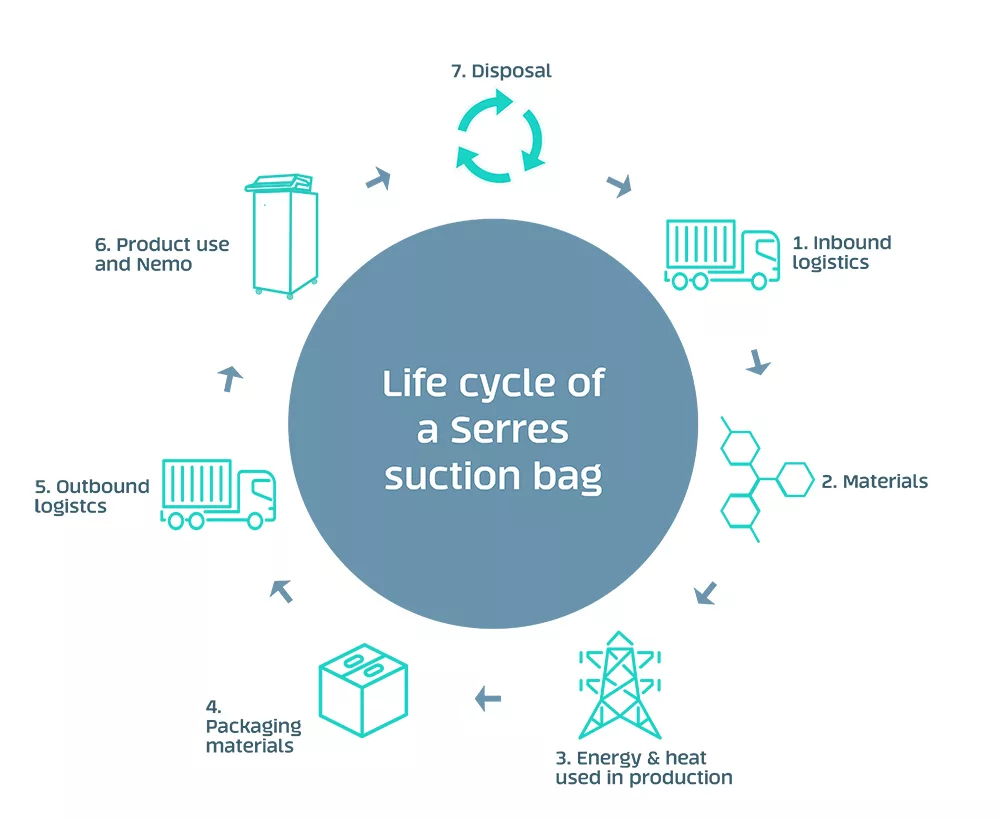

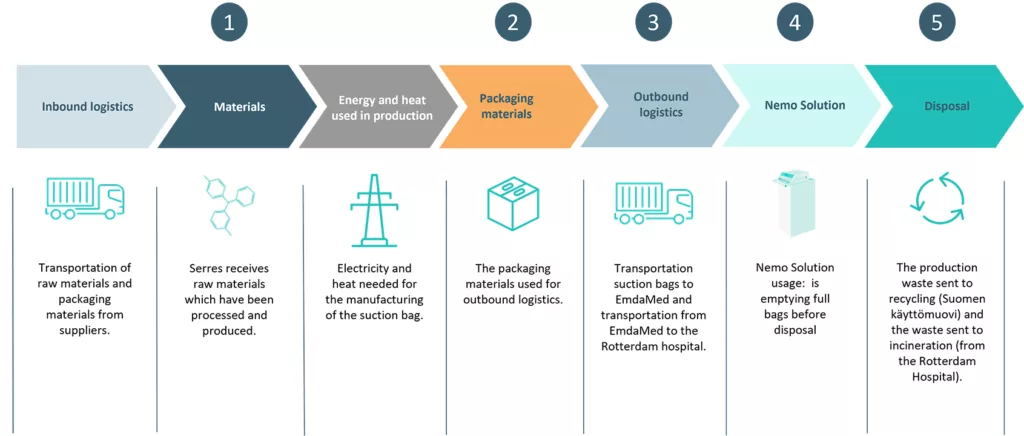

The steps

- Inbound logistics

- Materials (suction bag and Nemo solution)

- Energy & heat used in suction bag production

- Packaging materials

- Outbound logistics

- Product use (emptying suction bag with Nemo solution)

- Disposal (transportation of used suction bags to waste incineration)

The carbon footprint of a 2l Serres Suction bag

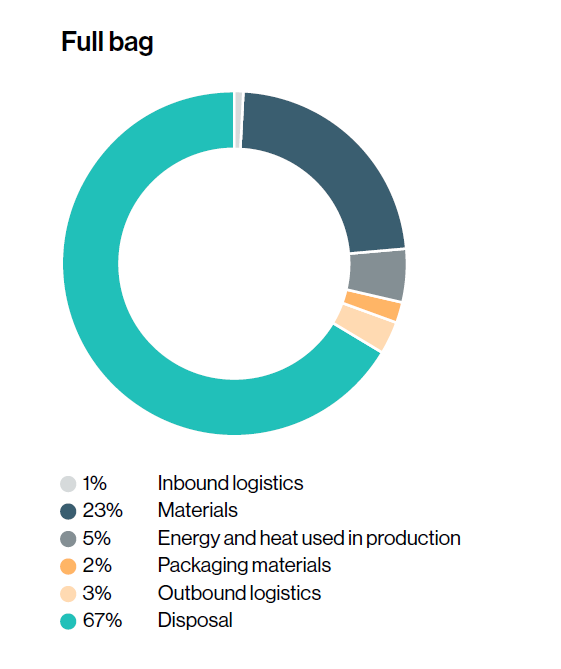

The full Serres Suction bag

The carbon footprint of the full Serres suction bag is 0.54kg CO₂e per bag.

The largest quantity of emissions comes from the disposal phase (67%) step 7. and the second largest comes from the raw materials (23%), step 2.

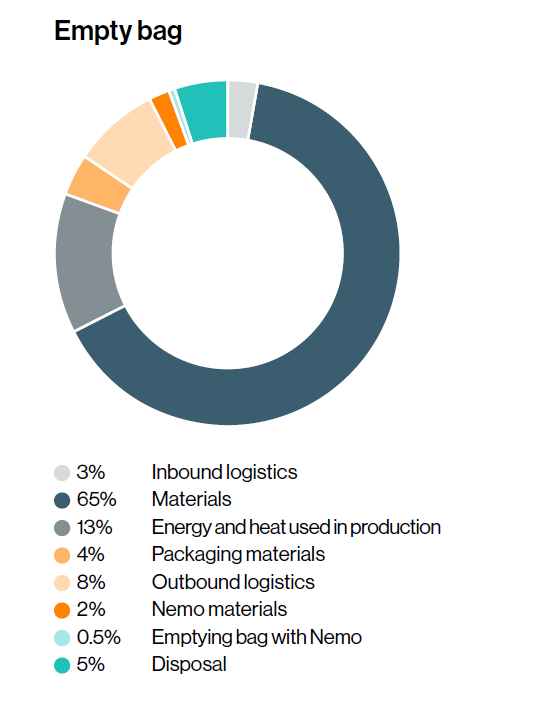

The emptied Serres Suction bag

The carbon footprint of the emptied 2l Serres suction bag is 0.20kg CO₂e.

The largest contributor to the total emissions for empty suction bags is raw materials (65%) (Step 2) and the second largest is the energy and heat used in production (13%) (step 7).

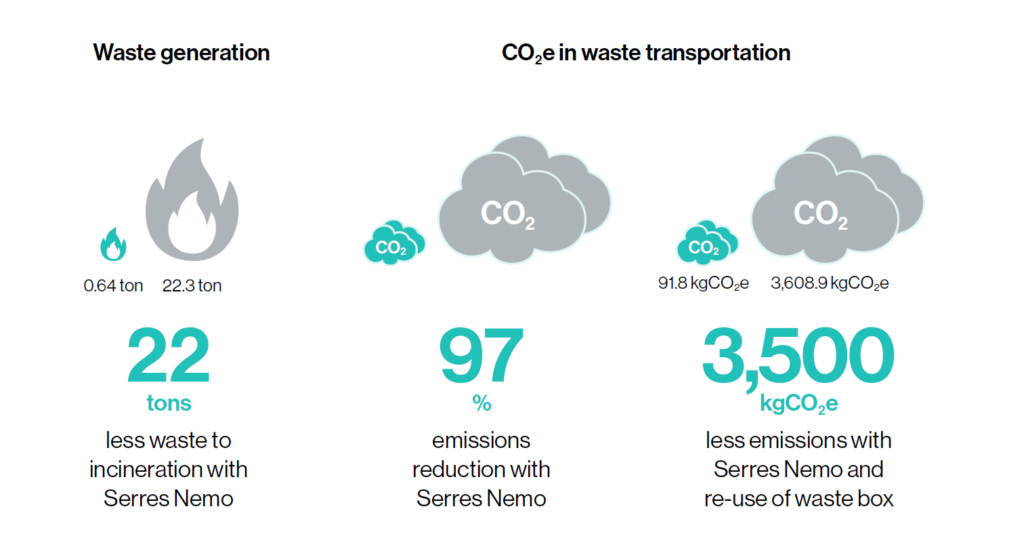

Saving up to 97% CO₂e emissions from waste disposal

The emission levels significantly rise in the disposal phase of the full bag scenario. Materials being transported for disposal need more space and have greater weight compared to the scenario involving empty bags. Moreover, the organic liquids contained within these bags are subjected to incineration and additionally, in the case of the Rotterdam Hospital, the full bags are transported to the incineration with plastic boxes and are incinerated with their contents.

NOTE: The disposal practices vary from country to country and even hospital to hospital. In the Rotterdam case, the full bags were transported in plastic boxes. Each fit 6 bags and the boxes were incinerated with the bags.

Toward carbon neutral hospital

5 ways to decrease carbon footprint in value chain / life cycle

After closely examining the carbon footprint calculations throughout our value chain, we noticed differences coming from mainly five specific points, where we and the hospitals can save CO₂ emissions.

- Design and amount of materials used in producing the suction bag

- Packaging materials and weight

- Outbound freight and distance

- Waste management practices

- Waste amount transported to disposal

You can read more about these steps in our blog post: Towards More Sustainable Healthcare: A 5-Step Approach to Decreasing Carbon Footprint in Hospitals

Sustainable design and use of smart materials

Over the years we have successfully reduced the amount of material used in the suction bag without compromising product quality. Today, our suction bags are the lightest bags in the market and do not contain any PVC, latex or DEPH. We are continuously investigating new raw materials, both recycled and recyclable, to continue being the forerunner in our field.

Serres Suction bag is exceptionally light and compact. The folded bag is unique with its patented folding design. Smart suction bag packaging reduces CO₂e emissions in transportation i.e. package design is scaled down to minimum size, maximized number of bags per package and empty space is minimized in the packaging. According to our study, this allows up to 4 times more Serres Suction bags to be packed in logistic packaging compared to similar products ***. Sea transportation from Finland to The Netherlands is used to reduce CO₂e emissions.

The share of recycled fiber in our suction bag dispenser package is 70% and in transport packaging 75%.

*Cradle-to-grave covers the entire lifecycle of a product. It’s a full analysis of a product from the raw materials to the disposal of the product to asses its full carbon footprint. In 2023 we will complete the the scientific method in our calculation.

** Our Inventory analysis and system boundaries in more detail

- Inbound logistics – Included: Transportation of raw materials and packaging materials from suppliers.

- Materials -Included: Emissions from extraction and production of raw materials. It consists of the “cradle to gate” phase. Excluded: Packaging materials where raw materials were distributed to the Kauhajoki factory are excluded since their influence is not significant. (The weight of the packaging material is approximately 0.5 percent of the weight of the transported material.) The minerals were excluded from the calculations.

- Energy & heat used in production – This phase includes the electricity and heat needed for the manufacturing of the suction bag.

- Packaging materials – Includes all the packaging materials used for outbound logistics.

- Nemo solution and packaging – Included: Stainless steel and ABS plastic used for Nemo. Included the cardboard, foam, and pallets for the transportation. We have included on p. 15 how much water would be used in Rotterdam. Excluded: Emissions related to manufacturingof Nemo and electronic components in the Nemo solution are excluded. Detergent use has been excluded. Emissions from the Transportation of Nemo to the Rotterdam Hospital are excluded. When Nemo is in standby mode, electricity use is excluded.

- Outbound logistics – Included: Transportation of finished suction bags to our distributor partner in the Netherlands. Excluded: Transportation from our partner to Rotterdam Hospital. Excluded:

- Disposal – Including the excess materials thrown into disposal which are produced in the Kauhajoki factory and the disposal of the suction bag from the Rotterdam hospital. Both options for disposal of full and emptied suction bags are calculated separately. We have included waste transportation to incineration. Excluded: Disposal phase of packaging materials is excluded (excluding cardboard boxes, since the emission factor used contains the cradle to grave carbon footprint of a cardboard box (without transportation)).

- Other – The disposal phase of packaging materials is excluded (excluding cardboard boxes, since the emission factor used contains the cradle-to-grave carbon footprint of a cardboard box (without transportation)).

*** Packaging & logistics efficiency comparison is based on market analysis & study on number of similar-use products in 1 package & pallet efficiency in trucks and containers. Study was conducted in 2023.

What is the carbon footprint?

A carbon footprint refers to the total amount of greenhouse gases (primarily carbon dioxide) emitted directly or indirectly by a person or other entity such as a building, company, animal, etc. In addition, the carbon footprint concept can also include the emissions of other greenhouse gases, such as methane, nitrous oxide, or chlorofluorocarbons (CFCs). Carbon footprint quantifies the impact of our daily choices, including energy consumption, transportation, manufacturing processes, and waste generation. The unit of measurement is usually in metric tons of carbon dioxide equivalent (CO₂e).